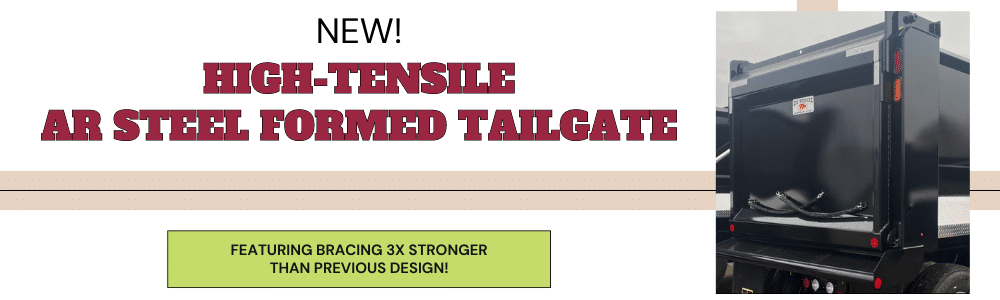

Ox Bodies’ New AR Steel Formed Tailgate Design

Tailgates play a critical role in dump bodies, serving as the gateway to releasing material. However, the constant exposure to demanding loads and harsh environments means tailgates often endure significant wear and tear. To meet this challenge head-on, Ox Bodies has developed an innovative solution – our new formed tailgate design, now standard on Chisholm & Stampede models.

This reimagined tailgate design embraces the inherent strength of high-tensile, abrasion-resistant (AR) steel, creating a formidable barrier against the rigors of heavy-duty hauling. Ox Bodies’ engineers eliminated welds that are frequent failure points of conventional tailgates, making our new design exceptionally durable by comparison. This level of reliability builds trust with drivers and operators, knowing they can rely on the tailgate’s strength when it matters most.

Key Features of the New Tailgate Design

Central to the new tailgate’s excellence is the use of high-tensile AR steel, the industry’s strongest and most durable material. Our engineering team’s extensive testing and validation processes ensure that this material is optimally integrated into the design, enhancing the tailgate’s longevity and performance.

With a hardness factor that is 3x that of common steel, this innovative tailgate also provides much more resistance to abrasive wear from sand, gravel, and other tough materials. The horizontal bracing structure is integrated into the AR tailgate plate. This means that the horizontal weld joints are eliminated. The deposited material in typical welded joints only has 1/3 the tensile strength of the AR plate.

One of the most significant advantages of utilizing formed AR steel is that it allows our engineers to create bracing that is 3x stronger than the prior design and eliminate the need for additional bracing. By doing so, Ox Bodies not only simplifies the tailgate’s construction but also avoids potential weak points that could compromise its integrity over time. The absence of welds and heat-affected zones reinforces the tailgate’s strength and reliability, setting it apart from traditional designs. As an added bonus, the unobstructed center panel is ideal for adding signage and promotion.

Boosting Productivity: How Our Tailgate Saves Time and Resources

As one of the most exposed components in a dump body, tailgates directly impact productivity. The new formed design allows the tailgate to endure the relentless demands of daily operations, reducing maintenance needs and downtime.

This newfound durability translates into cost savings for businesses, as they can expect longer service life and fewer repairs. The angled surfaces of the tailgate also play a crucial role in enhancing productivity by shedding debris, keeping the tailgate clean and ready for efficient emptying.

Conclusion

Ox Bodies’ new formed tailgate showcases our relentless pursuit of innovation and excellence in hauling solutions. As a vital part of a dump body, the new tailgate stands as a testament to the power of formed, high-tensile, abrasion-resistant steel and its ability to create a more durable, long-lasting, and efficient component.

By addressing the challenges of wear and tear head-on, Ox Bodies has once again demonstrated its commitment to providing cutting-edge solutions that empower businesses to thrive in the most demanding environments. Embrace the strength and reliability of Ox Bodies’ formed tailgate and take your hauling operations to new heights of performance.